2024 CHINAPLAS Interview | JANDI’S

We are here with Tony from JANDI’S at the CHINAPLAS. JANDI’S INDUSTRIAL CO., LTD. is committed to developing blown film machines combined with bag-making, printing, and recycling machines. They obtained more than 30 patents for plastic machinery in China and Taiwan. With the concept of plastic reduction raising, JANDI’S proposes an idea about green innovation. The company develops JIT series integrated plastic bag-making machines that are 100% suitable with biodegradable and compost materials such as PBAT and PLA. Moreover, JANDI’S added the automatic packaging part to JIT series.

FSL-TR series Turret Rewind Slitting Machine | HCI

HCI’s newly launched FSL-TR1300 turret rewind slitting machine is designed for automatic slitting and rewinding operations, with automatic splicing and roll changing, stand-by paper core auto positioning, finished roll pusher and unloading device to increase productivity and reduce the operation down time. The HMI operating system equipped with a color touch screen provides easy-to-learn operations and memory of operating parameters, which makes the product quality stable.

High Speed T Shirt Bag Making Machine|PLAS ALLIANCE

T Shirt Bag Bag On Roll with core auto insert system - 32RTWDFA-VR-2 Plas Alliance has a variety of plastic bag on roll machines for customers to choose, and is committed to innovation and research and development. So far, it has developed a variety of bag making machines for various bag formats. 【T-Shirt Bag On Roll Making Machine Features】 High speed Continue feeding system available in 200/250/300rpm systems. Tension-less sealing avoids sealing line pull & elongation for high-speed production. Rotary Die cut by Magnetic cylinder with simple die cut blade exchange. Inverter controlled feeding matching main machine speed for easy operation without manual adjustment. Support to work for Jumbo film slitting into two separate roll with post gusset in line system by Option (or model : 36RTWDFA-VR+SLG2) Equipped with LCD touch panel, easy to operate Switch control to exchange bag making process without adjustment Bag re-wind in roll , paper CORE insert in line automatic End of Film, core auto STOP 【Machine Available System】 Tension-less sealing T shirt bag on roll Flat bag on roll S type bag on roll 【Company Intro】 “PAL- Working with you to create all types of bag making automation solutions!” Like the first companies in 1988 to create the first bottom seal bag machine started, and since then, we have been studying bag machine design, manufacturing, innovation and change with the bag, we have always kept up to date technology, continue to explore, develop more labor-saving, cost-saving bag machinery, to provide customers with a complete bag packaging solutions, growing up with customers, a business partner to create the pinnacle!

Rotary Table Injection Molding Machine | TAIWAN KINKI

MACHINERY IN THE VIDEO: Rotary Table Injection Molding Machine with Full Auto System from TAIWAN KINKI (TKC) [TAIWAN KINKI LINES OF BUSINESS] Production of vertical plastic injection molding machines. Design of automatic injection molding machinery. Turn-key plants for accessories and peripherals for injection machinery. Injection mold design and manufacturing. Electrodeposition, powder coating, baking enamel, and leather treatment. Agency of the vertical injection machine and Zinc alloy coating. [APPLICATIONS] Especially suitable to manufacture Automobile Parts [TAIWAN KINKI (TKC) BACKGROUND] TKC had over 40 years of experience in Vertical Injection Molding Machine manufacturing. The company offers a full series of vertical injection molding machine portfolios including Standard, Slide, and Rotary table models. TKC also offers mold design and a full auto system for customer's products.

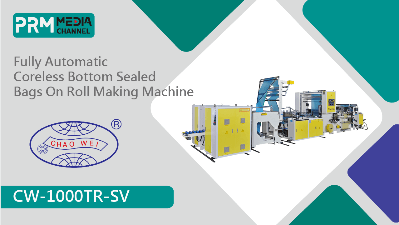

Fully Automatic Coreless Bottom Sealed Bags On Roll Making Machine | CHAO WEI

【Machine Spec & Features】 Bottom Sealed Bags On Roll Making Machine (Coreless) Film width: 600 mm / Thickness: 15 micron E.P.C Control & Rollers Device (E+L, German made) Length: 750 mm x Speed: 135 Pcs/Min Production Line Speed: 100M/Min Servo Driven Shuttle Type Sealing & Perforating Unit Two Sets Triangle Folders For Making Finished Roll With Small Width Machine Maintains High Speed Production By 4 Sets Rewinding Shafts While Producing Small Quantity Of Bags Per Roll 【Company Introduction】 Chao Wei Plastic Machinery is an advanced manufacturer of plastic bag making machine with more than 35 years of experience with ISO 9001 & CE certificates in Taiwan. One of the reasons for the excellence of Chao Wei’s machines is our dedication to research and development.

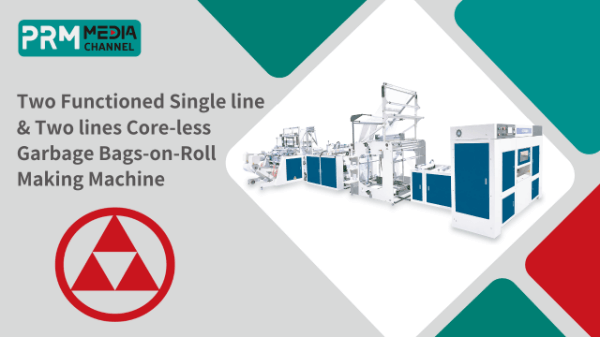

Two Functioned Bags on Roll Making Machine:SR(2)MR(1)-1000-OS-2T-R4S | COSMO

Fully Automatic High Speed Two Functioned Single Line & Two Lines Core-less Garbage Bags on Roll Making Machine Machine Model : SR(2)MR(1)-1000-OS-2T-R4S Machine Name:PHENIX • Core-less bags on roll • star sealing bags / Bottom sealing bags with V, C, N, M shape • Shuttle sealing & feeding system • Four shafts re-wind system

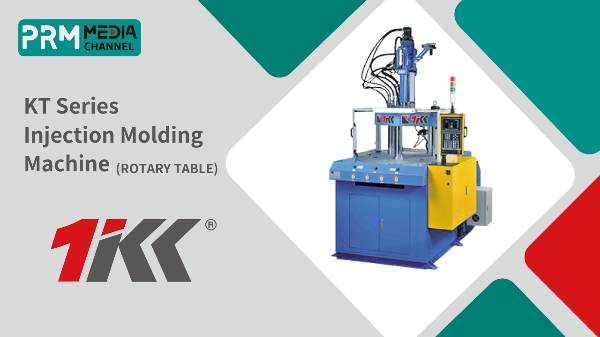

KT Series Injection Molding Machine (ROTARY TABLE) | TAIWAN KINKI

KT Series Injection Molding Machine Vertical mold clamping and injection, small footprint and high degree of precision. This machine is ideal for injection of medium and small products with inclusions. Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for production of thin items. Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation. Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects. This machine offers a wide range of programmable functions including automatic inclusion, extraction and fully-automatic production. There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

Plastic Recycling & Pelletizing Machine | GEORDING

【Product Line】 Plastic recycling machine Compounding machine Dyeing & Pelletizing Automatic batch weighing and mixing system Washing line Rubbing drying machine Powerful crusher Shredder Plastic flat board extruder Refuse derived fuel (RDF) 【Company Intro】 GEORDING MACHINERY CO., LTD. has dedicated to innovating their machines with superior features which can process various plastic materials, such as PA, PET, ABS, TPU, Calcium Carbonate and even PE foam. By keeping developing and improving their technology, GEORDING has become one of the leaders of the extruder supplier as well.

Quick Mold Change | FORWELL

Quick Mold Change - Quick Mold Change System-forwell-qmcs-en-Forwell Features • Decreased mold change time • Fully customizable to fit a wide range of machines • Safer operations • Reduced labor costs • Easy changeover for small batch runs System Introduction : Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety. Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds. Quick Mold Change Systems can rapidly transform your workshop, allowing for easy changeover for small batches, reduced labor costs and reduced stock holding. Coupling this system with a Mold Cart System will allow for fully automatic mold changing, further increasing the efficiency and productivity of your manufacturing operations.

Plastic Bag Making Machine | WorldSteel

Suitable for a range of shapes folds and pockets, interlinking with other equipment to be able to make even more types of bags for easy exchange. Pattern types include: punching equipment for round holes, butterfly holes, utilizes handheld punching equipment for accuracy and can produce perforations for letter and packaging tear off strips. Using a vertical up and down heat sealing system and supersonic sealing line device. Provide extra parts for improved production accuracy and quality, including EPC edge sensor, servo motor to drive the machinery and an automatic conveyor to get your finished products to the packing section as soon as possible. Suitable for already perforated and/or folded films. 【Company Introduction】 World Steel Machinery Company is dedicated to making technological innovations and manufacturing packaging machines.They have the best engineering crew in the industry to provide total solutions which include design, customization and development. If you are looking for machines that produce, flower sleeves, diaper bags, book sleeves, self adhesive bags, handle bags, sandwich bags or more, then World Steel is the best choice for you.

High Speed 2 Lines Coreless Bag on Roll Trash Bag Making Machine | CHAO WEI

High Speed Fully Automatic 2 Lines Coreless Bag on Roll Trash Bag Making Machine | CHAO WEI, TAIWAN [DESCRIPTION of the Machine] ⚡️Special for two lines perforating coreless bottom and star sealing bags on roll. ⚡️In-line triangle folding device for star sealing bags. ⚡️E.P.C. (Edge Position Control) for the film at correct position. ⚡️Japan made servo motors & servo drivers control bag length precisely and high speed production, reducing electric consumption. ⚡️Bag length & production speed can be changed easily from touch screen. ⚡️German made photocell-SICK for accurate printing mark. ⚡️Automatic lift up reel unwinder with air shaft, reducing the number of employees. ⚡️Automatic tension control with AC motor and inverter system for jumbo diameter film roll. ⚡️Two lines automatic roll changing system.

PP Woven Bag Fully Automatic Liner Inserting-Bag Top Hemming Conversion Line | BOTHEVEN

【MAIN FEATURE】 All in one multi-functional machine - Flexible Usage for various type of PP woven bag Processing on the same machine. Available for PP woven bags: ● With liner Inserting-Cutting-Sewing and bag top hemming process ● With Cutting-Sewing and Bag Top Hemming Process Only (Without Liner Inserting) ● With Liner Inserting-Cutting-Sewing Only (Without Bag Top Hemming process) Cutting-Sewing Process only (Without Liner Inserting & Without Bag Top Hemming) Saving Manpower, Space and Saving Cultivated Training for Skilled Manual Operation to the Maximum. Producing Finished Bags with Conformed & unified quality with stable performance Experiencing Clean Process of Bag Top Hemming, largely Reducing Hang-Touching on the bag top area. Highly synchronized machine for Easy Setup and quick bag size changeover. A Total-Solution Machine for PP woven bags with Final Products Applicable in a Big Variety Market. 【COMPANY INTRO】 Botheven Machinery Industrial Co., Ltd, (Since 1984), has accumulated more than 30 years of technical experience & know-how in the planning design, manufacturing, sales and service of PP/HDPE Woven Bag Making Machines in Taiwan. Our equipment has been sold worldwide with assured quality, stable performance and reliable after-sales services. We can build machinery according to customers' requirement; also provide cost-down solution for customers.